The Rise of Agentic Enterprises in Manufacturing: Vietnam and Global

- Publised February, 2026

Discover how the rise of agentic enterprises in manufacturing is reshaping factories through AI-driven autonomy, orchestration, and real-time decision making.

Table of Contents

Toggle

Key Takeaways

Agentic AI refers to AI “agents” that can perceive context, make decisions, and take actions independently, moving beyond traditional automation or generative AI that only analyzes data or generates content. In manufacturing, this means intelligent systems not only identify issues or insights but act on them across production and supply chain workflows.

- Early adopters report tangible performance improvements. AI agents can optimize production schedules, maintenance, and logistics in real time – boosting productivity and cutting costs.

- Agentic enterprises build adaptability into their processes. AI agents monitor quality 24/7, catching defects or anomalies faster than human checks, and can adjust processes on the fly to maintain standards.

- Rather than replacing people, agentic systems augment the workforce. By automating repetitive tasks and routine decisions, they free employees to focus on creative problem-solving, innovation, and strategic work.

Understanding Agentic Enterprises in Manufacturing

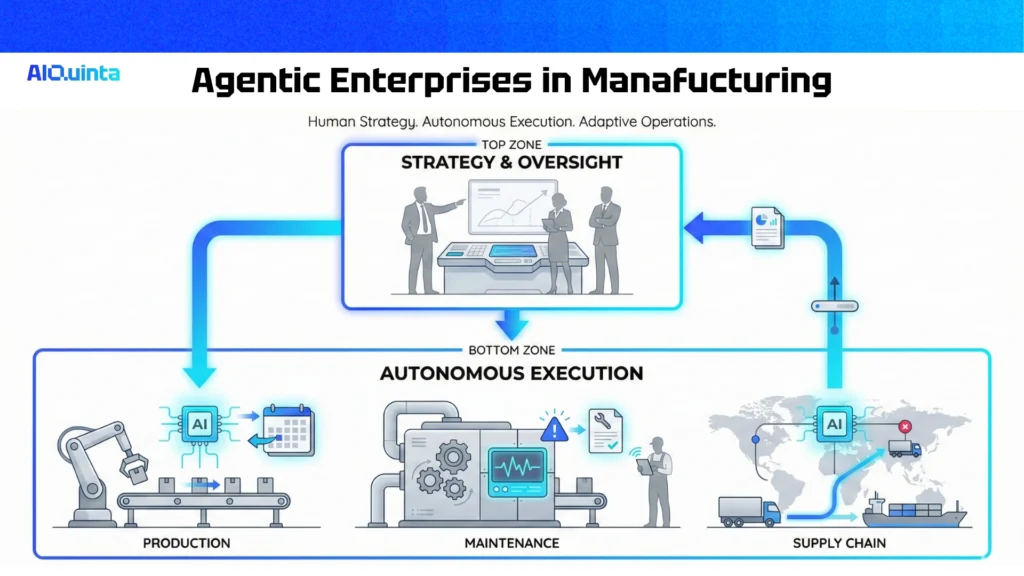

In today’s volatile industrial landscape, manufacturers are turning to a new class of AI-powered automation to stay competitive. Agentic enterprises are organizations that embed AI agents throughout their business processes – not as isolated tools, but as an integrated “digital workforce” operating alongside humans. An AI agent in this context is a software entity that can observe its environment, make decisions, and execute actions to achieve specific goals with minimal human intervention. In manufacturing, this could be an AI system that continuously monitors production lines and automatically adjusts schedules, or a supply chain assistant that reschedules deliveries in response to a logistics delay.

How is agentic AI different from earlier automation? Traditional automation follows pre-programmed rules, and even advanced generative AI focuses on producing insights or content. Agentic AI goes further – it can reason and act within defined parameters. For example, instead of just alerting a manager about a machinery fault, an agentic system might proactively order a replacement part and schedule maintenance to fix the issue. This ability to autonomously translate decisions into actions is what makes agentic enterprises a potential game-changer for manufacturing efficiency and agility.

Crucially, agentic AI doesn’t operate in a vacuum – it works in tandem with human teams. The goal is not to replace human workers, but to offload low-value and time-critical tasks to AI. As one industry executive noted, companies increasingly want systems that “don’t simply notify them of issues but help resolve them”. In an agentic enterprise, front-line staff and managers partner with AI agents: routine decisions and adjustments are handled by machines, while humans focus on strategic planning, creative problem-solving, and oversight.

This human+AI collaboration can fundamentally redefine roles and workflows. Imagine production planners who supervise fleets of digital agents orchestrating materials and schedules, or maintenance teams who receive AI-driven predictive insights instead of performing fixed-interval equipment checks. The entire organization becomes more fluid and responsive, with a “digital layer” of agents continuously working to optimize outcomes. It’s a dramatic shift – proponents call it the biggest workplace transformation since the Industrial Revolution.

Why Agentic AI is on the rise now

Although AI in manufacturing isn’t new, several recent developments have accelerated the rise of agentic enterprises:

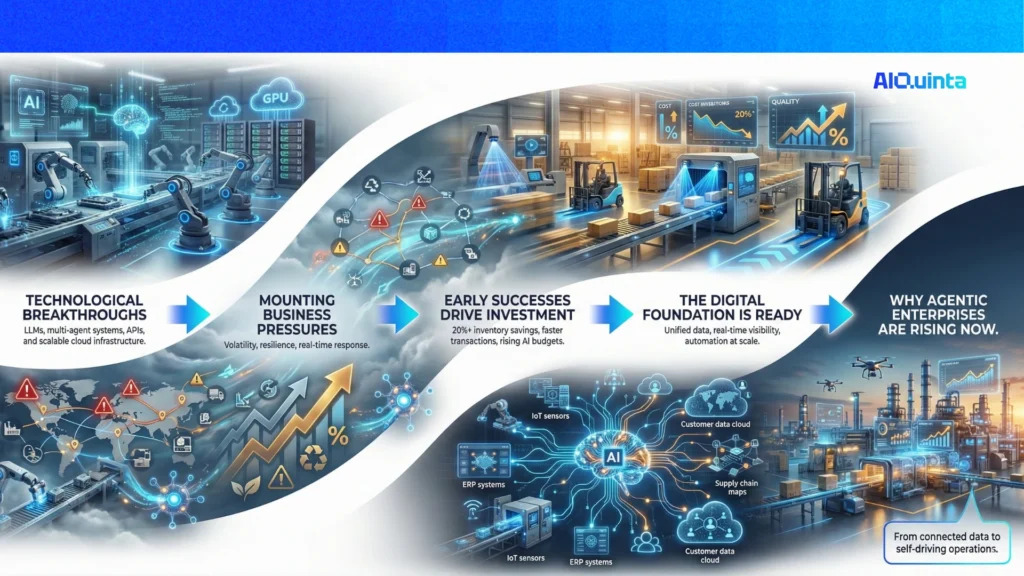

Technological Breakthroughs: Advances in AI, particularly large language models and multi-agent systems, have empowered software agents with much better context understanding and reasoning abilities. Modern agents can analyze unstructured data, communicate with other systems via APIs, and handle complex decision logic that once required human judgment. Moreover, improved GPU/cloud infrastructure has made it feasible to deploy these AI workloads at scale. In short, the tech needed for truly autonomous agents has matured rapidly in the past couple of years.

Mounting Business Pressures: Manufacturers today face unprecedented volatility – from supply chain disruptions and cost pressures to heightened quality and sustainability demands. Many firms learned during recent crises that purely manual or rigidly automated processes couldn’t adapt fast enough. This has created a strong pull for AI solutions that offer agility and resilience by design. Agentic AI promises exactly that: systems that can respond in real time to surprises (a machine breakdown, a sudden order spike, a shipment delay) and take corrective action instantly. The appeal of a self-adjusting, always-on operation has never been greater.

Early Successes Fueling Investment: Pioneering deployments of agentic AI have delivered eye-opening results, building confidence in this approach. For example, manufacturers have improved defect detection rates by using AI vision agents on the line, and logistics operations using autonomous scheduling agents achieved 20%+ reductions in inventory and freight costs. Transaction processes that once took days have been cut to minutes by intelligent workflow agents. Seeing these wins, industry surveys indicate a wave of investment: over three-quarters of manufacturers plan to increase AI spending in the next year (with most expecting double-digit percentage increases). Analysts project the manufacturing AI market (fueled by agentic systems) will surge from $34B in 2025 to over $150B by 2030. In short, the ROI is becoming evident, and no one wants to be left behind.

The Digital Foundation is Set: Another reason agentic enterprises are emerging now is that many manufacturers have spent the past decade on digital transformation – implementing IoT sensors, unified data platforms, and advanced analytics. Those efforts laid a foundation of connected data and systems. Now, agentic AI can be the “brain” acting on that nervous system. Companies that unified their factory machines, ERP, supply chain and customer data are finding they can plug in AI agents to leverage that integration. As one report notes, once data silos are removed and real-time visibility achieved, it’s natural to layer AI on top so that insights turn into automated actions across departments. In essence, the smarter and more connected your operations, the more impactful AI agents can be – and many firms are finally at that point.

AIQuinta – Digitize all data from the production layer to the highest management layer & Embed Agentic AI to Analyze and Optimize Production.

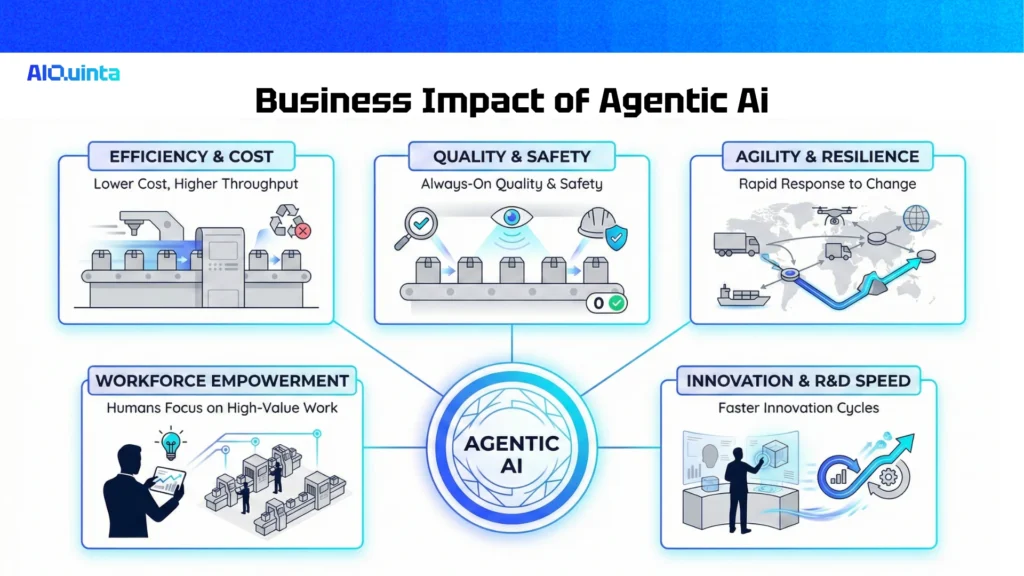

Benefits of Embracing Agentic AI in Manufacturing

The move toward agentic AI isn’t just a tech trend – it delivers concrete business value. Key benefits include:

Improved Operational Efficiency and Cost Reduction

Intelligent agents excel at streamlining operations. They analyze production data, supply levels, and workflows continuously, finding ways to eliminate bottlenecks and waste.

For instance, AI agents can optimize machine schedules and adjust line speeds on the fly to maximize throughput. They can also predict equipment failures from sensor data, allowing maintenance to be scheduled at optimal times to avoid downtime.

These efficiencies translate into major cost savings. Automation of repetitive tasks and smarter resource allocation can cut labor and energy costs significantly.

In fact, some early implementations have achieved productivity gains as high as 50–60% in certain tasks. By reducing overproduction, downtime, and defects, agentic systems attack the biggest cost drivers in manufacturing. Even inventory costs shrink, as agents balance stock levels and reorder supplies just-in-time.

The bottom line is a leaner, faster operation – doing more with less human effort, which improves margins.

Enhanced Quality and Safety

Agentic AI brings an unwavering focus to quality control and safety. Unlike human inspectors who sample output or do periodic checks, AI vision and sensor agents can monitor 100% of production in real time.

They can instantly detect defects or anomalies beyond set thresholds and even adjust machine settings or trigger corrections to prevent faulty products. This reduces scrap and rework, and ultimately leads to fewer customer complaints or recalls.

One source notes automated inspections with AI can cut quality issues by up to 60%, safeguarding brand reputation. Moreover, agents never get tired or distracted – they watch over operations 24/7, which also enhances safety. They can catch overheating equipment, flag safety hazards, or enforce compliance steps (for example, ensuring a machine is shut down before maintenance).

In high-risk environments, having “digital eyes and ears” everywhere provides a new level of assurance. Quality and compliance metrics improve, and employees are safer with routine hazards proactively managed by AI.

Greater Agility and Resilience

In a world of fragile supply chains and fast-changing demand, agility is a prized asset. Agentic enterprises gain unmatched flexibility because their AI systems can rapidly adapt to new information.

If a supplier shipment is delayed, an AI agent might automatically re-route orders to alternate suppliers or redistribute stock from another warehouse, mitigating a potential disruption within minutes.

If demand spikes unexpectedly, production agents can swiftly authorize overtime runs or reprioritize manufacturing schedules to fulfill orders faster.

This dynamic adjustment extends to many areas: inventory agents that rebalance stock across locations, logistics agents that re-optimize delivery routes daily, or planning agents that constantly refine forecasts.

The result is an operation that responds to shocks and opportunities with far less manual firefighting. Companies can run leaner (carrying less inventory buffer, for example) because they trust the system to handle volatility.

According to industry leaders, resilience through real-time autonomy is a key reason to deploy agentic AI – it’s like having a self-healing supply chain and a self-optimizing factory, which is invaluable when disruptions strike.

Innovation and R&D Acceleration

Agentic AI is also proving to be a catalyst for faster innovation in manufacturing. By serving as tireless research assistants, AI agents can dramatically speed up R&D and continuous improvement efforts.

For example, in product development, generative design agents can suggest and virtually test hundreds of design iterations that meet specified goals (weight, strength, cost, etc.) in a fraction of the time it would take human engineers.

One study found AI can accelerate R&D processes by 20–80% for complex manufactured products when used optimally. Similarly, in process engineering, an AI agent can simulate and fine-tune a manufacturing process (or a digital twin of the factory) to identify optimal settings much faster than trial-and-error on the shop floor.

These agents effectively become “always-on” digital researchers for the company – learning from each experiment or production run and applying those learnings to propose improvements. This continuous, AI-driven experimentation fuels innovation in product design, process efficiency, and even new business models.

Companies that embrace agentic AI often find that they can iterate and improve at a much faster pace, gaining an edge in innovation over competitors stuck in manual processes.

Empowered Workforce and Higher-Value Jobs

Rather than making people obsolete, agentic enterprises redefine jobs in positive ways. By automating drudgery, AI agents unburden employees from monotonous tasks, allowing them to focus on work that truly requires human creativity, insight, and leadership.

For instance, instead of spending hours each day monitoring production KPIs and troubleshooting minor issues, a plant manager can rely on AI to handle monitoring and only intervene when strategic decisions or complex exceptions arise. Workers on the factory floor might transition into roles as “orchestrators” of AI and machinery – managing systems, analyzing AI-driven insights, and engaging in continuous improvement projects.

This shift can boost job satisfaction and engagement, as employees devote more time to problem-solving and innovation rather than rote tasks. Notably, companies implementing agentic AI often invest in upskilling their workforce – training staff in data analysis, AI oversight, and other digital skills.

Over time, the organization builds a culture where humans and AI collaborate, each doing what they do best. People are still critical to manufacturing, but their roles evolve to oversee the technology, handle exceptions, and drive strategic growth.

As a bonus, by making workers’ jobs less tedious and more impactful, agentic enterprises may find it easier to attract and retain talent in an industry that has historically struggled to do so.

Sustainability and Compliance Gains

Agentic AI also helps manufacturers meet their sustainability and compliance goals. Autonomous optimization means less waste – AI can tweak processes to minimize scrap material, reduce energy consumption, and prolong equipment life (which means fewer replacements).

For example, predictive maintenance agents not only prevent breakdowns but also ensure machines run at peak efficiency, saving electricity and spare parts.

According to research, advanced maintenance techniques can cut downtime by up to 45% and reduce defects by as much as 65–95%, which implies less waste and rework. Additionally, AI systems can be programmed to factor in energy efficiency or carbon footprint when making decisions (such as scheduling production when renewable energy is available or routing deliveries to minimize fuel use). These kinds of intelligent adjustments help companies shrink their environmental footprint while still hitting production targets.

On the compliance side, having digital agents enforce rules and log all actions improves traceability and reporting.

For instance, in highly regulated sectors like aerospace or pharma, agentic AI can ensure every step in a process is documented and within spec, flagging any deviations immediately. The data transparency provided by these systems makes audits easier and assures regulators and customers that processes are under tight control.

Thus, agentic enterprises tend to be not only more productive, but also greener and more compliant – a dual win for profitability and corporate responsibility.

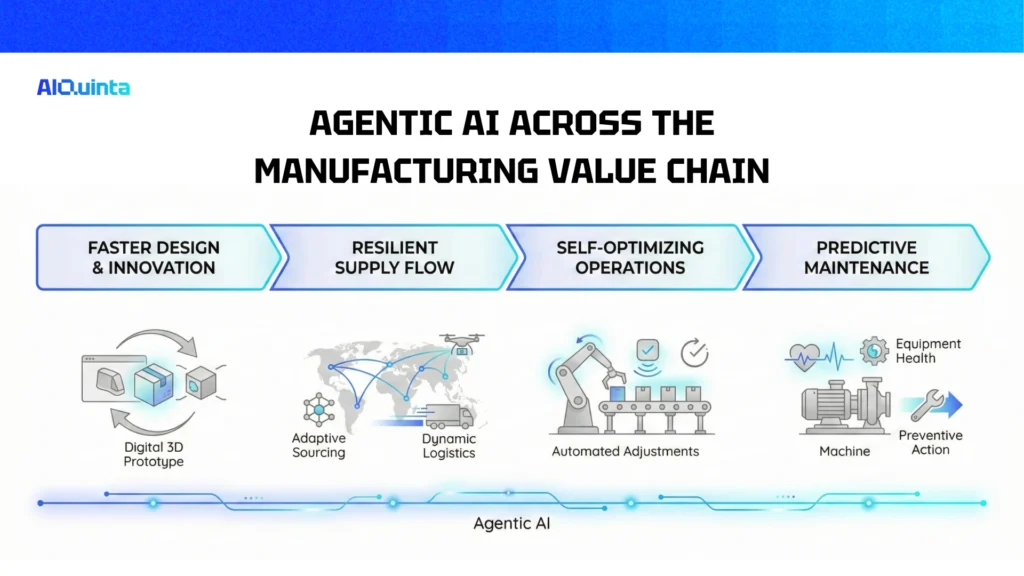

Applications Across the Manufacturing Value Chain

Agentic AI can be deployed at virtually every stage of manufacturing, from initial design to final delivery. Let’s look at how autonomous agents are transforming key parts of the value chain:

Research & Development (R&D) and Design

In the early phase of the manufacturing lifecycle, AI agents act as creative collaborators. They can rapidly sift through enormous datasets of material properties, past design successes and failures, and customer requirements to suggest optimal design choices. This includes generative design, where AI proposes new product designs that meet desired criteria, and simulating real-world performance to validate concepts.

An agent can, for example, explore countless combinations of materials or geometries for a component and highlight those that reduce weight while maintaining strength. By automating these exploratory tasks, companies drastically shorten development cycles.

Real-world example: a leading automotive supplier used a team of AI agents to generate initial test case scenarios for new product requirements, cutting what used to take engineers hours down to minutes. Such capabilities free human engineers to spend more time on truly novel problem-solving and innovation.

As these agentic R&D tools mature, they essentially become “always-on inventors” that continuously scan for improvements and new ideas, giving manufacturers a persistent innovation engine.

Procurement and Supply Chain Management

Sourcing raw materials and managing the supply chain is traditionally labor-intensive and prone to delays. Agentic AI introduces autonomy here by actively managing supplier interactions, orders, and logistics.

For instance, an AI agent can monitor global supplier data for any risks (like a supplier’s financial instability or a geopolitical issue) and proactively suggest alternate sourcing before a disruption occurs. Supply chain agents can also automatically place purchase orders up to a certain spend limit when inventory runs low, rather than waiting for human approval, thus preventing stockouts.

During distribution, logistics agents use real-time data to reroute shipments around bottlenecks – for example, if a port is congested or a delivery truck is stuck in traffic, the system might split shipments or reassign carriers to meet deadlines. The dynamic optimization of routes, inventory levels, and supplier selection leads to a more resilient and lean supply chain.

One striking capability is using digital twin simulations of the supply network: AI agents test different what-if scenarios (e.g. sudden demand spikes or a plant shutdown) in a virtual model and figure out the best response strategies. This means when real disruptions happen, the AI has essentially practiced for it and can execute an effective mitigation plan immediately.

Overall, agentic supply chain management can minimize delays, reduce carrying costs, and ensure materials and products keep flowing even under volatile conditions.

Production Operations and Quality Control

On the factory floor, agentic AI creates a more adaptive and self-optimizing operation. Traditional manufacturing lines are optimized for steady-state efficiency, but they struggle with variability. AI agents fix that by constantly monitoring production variables (temperature, speed, output quality, etc.) and making micro-adjustments in real time to keep things optimal.

If one machine slows down or starts producing defects, an AI agent could adjust upstream and downstream processes to prevent a bottleneck and alert maintenance if needed. This transforms production from a reactive process (where humans fix problems after they cause slowdowns or rejects) to a proactive, fluid process that self-corrects as conditions change.

Quality control is deeply integrated here: Vision AI agents inspect each product or component as it’s made, instantly removing defective items or tuning machine settings to address quality drifts.

For example, if an agent notices a pattern of minor blemishes on a painted part, it might adjust the paint spray parameters or trigger a quick calibration check – all autonomously. These interventions happen in seconds, not hours, ensuring that issues are caught before large batches are produced.

Additionally, manufacturing agents can manage dynamic scheduling and resource allocation. If a rush order comes in, the AI can reorganize the production sequence and labor assignments to accommodate it with minimal delay, or if a machine goes down, it redistributes tasks to other equipment.

The production floor effectively becomes self-organizing, with the AI choreographing people, machines, and materials for maximum efficiency and consistency.

Maintenance and Equipment Management

Maintenance is a prime area where agentic AI shines, shifting the approach from reactive fixes to predictive and prescriptive upkeep. AI agents continuously analyze data from machine sensors (vibrations, temperatures, error logs, etc.) to predict when a piece of equipment is likely to fail or degrade.

Far beyond simple scheduled maintenance, these agents account for real usage patterns and subtle signs of wear. When an issue is forecasted, the AI can automatically create a work order, schedule a repair during the optimal downtime window, and even order the necessary replacement parts. This means maintenance is done right before a failure would occur, greatly reducing unplanned downtime.

Research shows such predictive maintenance can reduce maintenance costs by 15–30% and eliminate up to 45% of unexpected breakdowns. Moreover, agentic systems increasingly use techniques like sensor fusion and anomaly detection: they can detect an anomaly (e.g., a machine’s energy consumption spikes abnormally) and immediately adjust operating parameters or trigger a safety shutdown to prevent damage.

In essence, the AI “takes care” of equipment health continuously. Some advanced implementations pair maintenance agents with robotic systems – for example, sending a maintenance robot to perform an inspection or minor fix under AI guidance without waiting for human technicians.

The result of agentic maintenance is near-zero unplanned downtime, longer equipment lifespan, and more reliable production schedules. It also enhances safety, as the AI can preempt hazardous breakdowns. And from a workforce perspective, maintenance staff move from routine checks to supervising the AI and handling the truly complex fixes, making their work more value-driven.

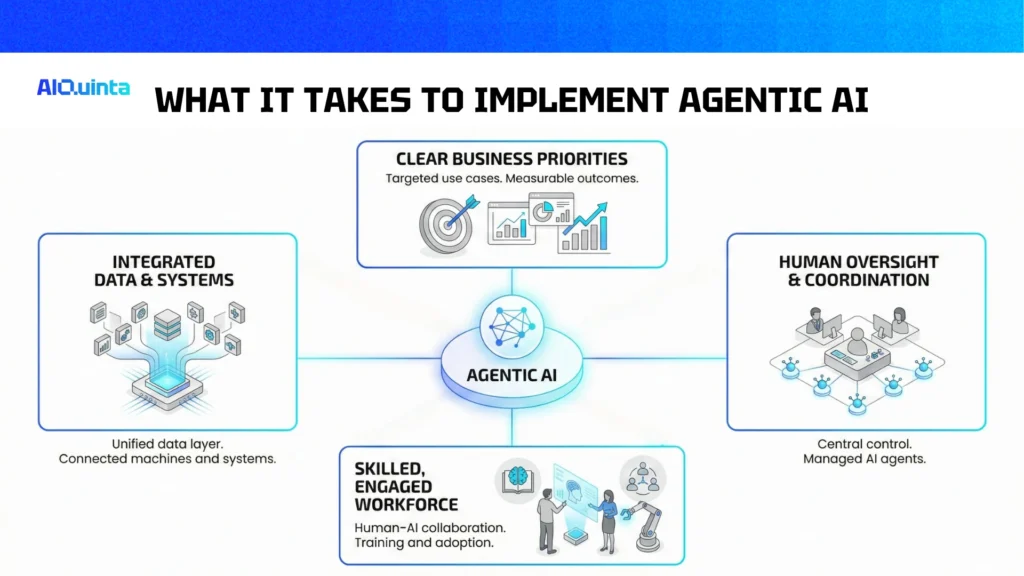

Challenges and Best Practices for Implementing Agentic AI

The benefits of agentic enterprises are compelling, but achieving them requires more than just installing new software. Companies must navigate several challenges and follow best practices to successfully integrate AI agents into their operations:

Digital Infrastructure and Data Readiness

A common refrain is that AI is only as good as the data feeding it. For autonomous agents to function correctly, manufacturers need integrated, high-quality data across machines and systems. This may entail upgrading legacy equipment with IoT sensors, adopting unified data platforms or “data lakes”, and ensuring different software systems can talk to each other.

Many leading firms have invested in modern MES/ERP systems and Industrial IoT connectivity precisely to break down silos. Those considering agentic AI should evaluate their digital maturity – if your production, inventory, and sales data all live in separate systems that don’t sync in real time, an AI agent will be handicapped. Building a strong digital foundation (sometimes called a “manufacturing data fabric” or unified namespace) is a critical first step. The payoff is that once data flows seamlessly, AI can be layered on to turn that information into intelligent action.

In short: integration before intelligence is a mantra of successful implementations.

AIQuinta – Digitize all data from the production layer to the highest management layer & Embed Agentic AI to Analyze and Optimize Production.

Strategic Alignment and Scope

Agentic AI should not be a technology experiment in a silo – it works best when aligned to strategic goals and reimagined processes. Companies should identify key pain points or opportunities (e.g. chronic bottlenecks, quality issues, slow planning cycles) and target those for AI agent solutions first. It may involve rethinking workflows entirely rather than just automating an existing step.

For example, instead of simply adding AI to an old quality inspection process, a manufacturer might redesign the process so that quality control is embedded at each production step with AI agents owning it end-to-end. This often means cross-functional collaboration (IT, operations, engineering, etc.) to redesign processes around what AI + human teams can do together.

A clear strategy helps avoid deploying agents as flashy gadgets that don’t actually move the needle. Start with use cases that have measurable ROI and align with business priorities (like reducing lead time or improving yield), then scale out.

Governance and “Agent Management”

As autonomous agents take on decisions, robust governance frameworks are essential to maintain control. Companies should establish policies on where and how AI can make decisions, and define escalation paths for exceptions.

It’s wise to start with a human-in-the-loop approach: allow the AI to make recommendations and even take actions, but keep humans informed and able to intervene as needed, until trust in the system grows.

Avoiding “agent sprawl” is a new challenge – if every department starts deploying their own agents, you could end up with dozens of AI systems operating independently and even at cross purposes. To prevent this, experts recommend centralized coordination of AI agents. This might mean having a chief AI officer or an AI governance board to oversee all agent deployments and ensure they integrate with each other.

Using open standards and interoperable platforms can help agents communicate and share data, rather than becoming isolated “black boxes”.

Monitoring is also key: develop metrics beyond just ROI to evaluate agent performance, such as decision accuracy, time saved, compliance maintained, and user satisfaction. By keeping a close eye on these metrics, companies can fine-tune agent behaviors and address any issues (for instance, if an agent starts making suboptimal decisions due to a data drift).

In short, treat your AI agents as a new kind of digital workforce that needs management, review, and continuous improvement – just like a human workforce.

Workforce Skills and Change Management

Introducing agentic AI will fail if the people in the organization are not brought along. It’s crucial to invest in training and change management so employees understand the new tools and how to work with them.

Upskilling programs in data literacy, AI basics, and process management help staff transition into new roles where they supervise or collaborate with AI agents.

Equally important is addressing employee concerns early: some workers may fear that “the robots are taking my job.” Leadership should communicate the vision that agentic AI is meant to empower employees, not replace them – by taking over mundane tasks and enabling more meaningful work. In many cases, companies reframe job descriptions (e.g. a machine operator becomes a “automation supervisor”) to reflect the new mix of responsibilities. Offering opportunities to work on higher-value projects or innovation initiatives can get employees excited about offloading grunt work to AI.

It’s also wise to involve end-users in the design and rollout of AI agent systems – for example, get input from planners on an AI scheduling assistant, or from technicians on a predictive maintenance tool.

This inclusive approach builds ownership and trust. A senior director of operations might champion pilot projects and highlight quick wins to build momentum. Remember that adopting agentic processes is as much a cultural transformation as a technological one. Open communication, training, and leadership support will smooth the journey.

Ethical and Security Considerations

With great power comes great responsibility. Autonomous decision-making systems introduce ethical and security questions that manufacturers must address. On the ethical side, consider the impact on jobs and how to retrain workers whose roles change – there is a responsibility to support your workforce through the transition (reskilling programs, etc.). Additionally, ensure that AI decisions are transparent and fair.

For instance, if an AI agent starts rescheduling shifts or reallocating work, employees should have insight into why those decisions are made and a way to appeal or question them if needed. Auditable AI logs and explainability features help maintain trust.

Data privacy is another consideration: agents will be consuming a lot of operational data, some of which might be sensitive (e.g. production secrets, supplier pricing). Companies need robust cybersecurity and data governance so that in giving AI more access, they are not creating new vulnerabilities. It’s advisable to work closely with IT and security teams to safeguard AI systems against hacking or misuse – a malicious actor compromising an AI agent could wreak havoc if, say, it controls equipment or financial transactions.

Ensuring compliance with regulations (for example, traceability requirements in pharma manufacturing or data protection laws) remains paramount, even as AI takes on tasks.

Ultimately, building trust in agentic systems – among employees, management, and stakeholders – is critical. This comes from demonstrating reliability, maintaining human oversight, and aligning AI actions with the company’s values and policies.

By anticipating these challenges and proactively managing them, manufacturers can unlock the full potential of agentic AI while avoiding pitfalls. The journey may involve some trial and error, but the experiences of early adopters provide a blueprint for what it takes to succeed: strong data foundations, clear strategy, vigilant governance, invested people, and ethical guardrails.

Conclusion

Manufacturing is entering a new era defined by autonomy and intelligence at every level of operation. The rise of agentic enterprises signals a fundamental shift in how factories and supply chains are run – one where AI agents handle routine decisions and actions in a coordinated symphony with human guidance. This transformation is already underway: companies that have embraced agentic AI are reporting faster production cycles, lower costs, better quality, and a newfound agility in the face of change. Just as importantly, they are laying the groundwork for continuous innovation, using AI to unlock insights and optimizations that were previously out of reach.

For manufacturers, the message is clear: those who harness agentic AI effectively stand to gain a major competitive advantage, and those who hesitate may find themselves falling behind more daring rivals. As one industry analysis put it, agentic AI offers a once-in-a-generation opportunity to rethink how factories operate and how work gets done. Early movers are not only achieving operational excellence but also pioneering new business models (such as more customized production or “as-a-service” offerings) enabled by autonomous capabilities.

Realizing this vision, however, requires thoughtful execution. Success depends on connecting data from the factory floor to management systems, orchestrating workflows across OT and IT, and deploying AI agents with strong governance and domain awareness. Platforms such as AIQuinta – An Agentic Enterprise Platform address this gap, enabling manufacturers to unify production data, embed agentic intelligence into daily operations, and scale optimization initiatives in a controlled and measurable way. The goal is not to replace people, but to amplify them, pairing the judgment of experienced engineers and managers with the speed and consistency of autonomous systems.

In summary, the rise of agentic enterprises in manufacturing is more than a tech trend – it’s a strategic evolution in how businesses compete and thrive. By embedding intelligence into the very fabric of their operations, manufacturers can become more resilient, responsive, and innovative than ever before. The tools and technologies are ready; the companies that act decisively to deploy them at scale will shape the future of industry. The question for every manufacturing leader now is: are you ready to join this revolution, or risk getting left behind?

FAQs

What is an agentic enterprise in manufacturing?

It is an operating model where autonomous AI agents manage planning, maintenance, quality, and logistics to achieve business goals with minimal manual intervention.

How is agentic enterprise different from industrial automation?

Automation follows rules. Agentic systems reason across goals, collaborate, and adapt to changing conditions.

What are the key benefits of adopting agentic enterprises?

Production scheduling, maintenance, supply chain, quality inspection, and energy management deliver the fastest ROI.

Your Knowledge, Your Agents, Your Control